3mm Maple-Faced Poplar Plywood, 600mm x 400mm sheet

This is a high-quality B/BB Maple-Faced Poplar Plywood sheet (laserply) that is suitable for a wide range of applications and is particularly suited to laser cutting. Both faces feature decorative Maple veneers and the core is of Poplar plywood. The Poplar core has a lower density and weight than Maple, meaning that it can be easily laser cut at lower power settings. Additionally, the poplar core means that the sheets are lighter than Maple plywood sheets. This Poplar core Plywood has a B/BB grading.

Please note:

As wood is a natural product, there is often a crook or bow to the sheet. The natural twist might be in excess of 25mm (see below – Tolerances and Caution).

The surface of the material will be consistent in appearance with no large variations in colour. Small pin knots are allowed and these would typically be only a few mm in diameter.

This plywood uses an EN314-2 Class 1 glue which is suitable for Interior (dry) conditions. Interior glue is generally considered the preferred option for materials that are to be laser cut. This is because the exterior glues can cause a more obvious ‘burnt’ look on and around the area that is cut.

Features:

- High-quality Maple faced Poplar core laser plywood sheets (laserply).

- Low-density core for easier laser cutting.

- Suitable for laser cutting.

- Interior grade glue.

Contents:

- 1 x 3mm Maple-Faced Poplar Plywood, 600mm x 400mm sheet.

Dimensions:

- Length: 600mm.

- Width: 400mm.

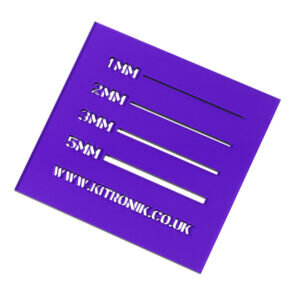

- Height: 3mm.

Video:

Watch this video below for information on how to use this product (please note: other Kitronik products are included in this video).

Tolerances:

The manufacturing tolerance for the thickness of plywood sheets are the stated thickness +0.2mm/-0.4mm. This means a 3mm plywood sheet could be between 2.6mm and 3.2mm in thickness.

Resources:

- Datasheet.

- A Guide to Plywood Grading.

Caution:

- As wood is a natural product there is often a bow or crook to plywood, and in some cases a twist. We have measured in excess of 25mm rise between the flat centre of the plywood and the corner. These twists are completely normal and add to the natural character of the plywood. If you are using this product on a laser cutter; these sheets should be strapped/taped to the laser bed before cutting.